Technical Newsletter vol.13 : Surface roughness determined by metal powder and binder

Surface roughness determined by metal powder and binder

Metal injection molding or MIM is a manufacturing method suitable for mass production of small and complex metal parts with complex final shapes, but small and complex parts are difficult to post-process. Therefore, the surface roughness obtained at the metal injection molding sintering process is often the surface roughness of the final product. This time, we will introduce the surface roughness realized by μ-MIM or Micro MIM technology.

Surface roughness depends on the particle size of the metal powder

Since MIM parts are produced without deforming the metal powder, it is no exaggeration to say that the particle size of the metal powder affects the surface roughness. Although it is affected by the surface condition of the mold that transfers the shape, it is necessary to use a metal powder with a small average particle diameter to obtain a surface with low surface roughness.

We have a track record of achieving Ra = 0.2μm in mass-produced products using metal powder with an average particle diameter of 2μm.

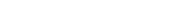

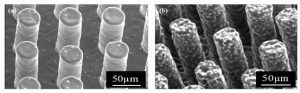

Figure 1 shows SEM observation images of micro pillars made of materials with different powder particle sizes. It can be seen that the smaller the average particle size, the better the transferability and the surface roughness.

Fig. 1: Micropillar made of SUS316L (a) Powder with an average particle size of 2μm, (b) Using an average particle size of 9μm

Fine metal powder is difficult to process

In MIM, the dispersibility of metal powder in the compact affects the mechanical properties and surface roughness. Fine metal powders tend to agglomerate, and it is essential to select an appropriate binder and control the powder. In addition, the specific surface area also increases, so unintended reactions with the binder are often seen. The price of fine metal powder is higher and the yield in the manufacturing process is low, therefore the delivery time tends to be long.

When using metal powder with a small average particle size, it is essential to select an appropriate kneader in the kneading process for making the feedstock as well as an appropriate binder. If an appropriate kneader is not used, the binder will not be kneaded so as to cover the metal powder, and the fluidity during molding will be significantly reduced. A decrease in fluidity leads to a decrease in product shape transfer ability and surface roughness.

Small metal parts with low surface roughness realized by μ-MIM technology

More than 10 years have passed since stainless powder with an average particle size of 2μm has been distributed, but feedstock using 2μm powder is not yet generally distributed. We have gained the knowledge of fine powder for more than 10 years and our feedstock realizes uniform dispersion in the compact while maintaining high fluidity of metal powder with such a small average particle size. Our μ-MIM technology enables stable mass production of complex micro components that meet the requirements of surface roughness.

Ref: www.intechopen.com, Powder Injection Molding of Metal and Ceramic Parts

C. Quinard et al. Development and properties identification of 316L stainless steel feedstock for PIM and μPIM, Powder Technol. 190 (1–2) (2009) 123–128.

COLUMN

This is Koji Miyazato of the quality assurance department. My work mainly includes the inspection of mass production parts and process management. I joined the company about 1 ½ years ago. My motto is to clearly switch ON / OFF between work and private. In my opinion, the ability to switch OFF work mode in your free time also affects the ability to focus when back at work. Recently I often go to the cinema, and watching the new Aladdin film moved me so I had to cry two times. I realized that I have become more emotional over the years and this is part of who I am.