Technical Newsletter vol.1 : Micronising metal powder injection moulding MIM

Challenge: micronising metal powder injection moulding (MIM)

The stand-out work on which prides itself namely includes ‘mass-producing precision parts with a net shape’ as well as handling ‘materials otherwise difficult to process’ and ‘production by tailor-made alloy’. Indeed leveraging MIM technology has also paved the way to mass-produce fine components previously considered infeasible, precision instruments and electrical and communication equipment and seen expectations soar in wide-ranging fields; automotive and medical among others. Compared to overseas, Japan also outperforms the rest in terms of scope to expedite delivery of precision moulds, with a ready supply of high-quality fine metal powder for MIM and exceptionally competitive MIM manufacturing technology. However, amid mass production in neighboring Asian countries, given the scope to drastically cut MIM manufacturing costs, progress in this area and globalisation looks set to soar in future. Moreover, demands imposed in terms of quality and delivery deadlines for domestic MIM products are becoming increasingly stringent, compared to precision-machining and lost wax methods. The drastically changing domestic and international conditions surrounding MIM underline just how crucial new developments that can showcase the advantages and technological capabilities of domestic MIM manufacturing really are and there is also a need to clearly point out just what the differences are. We will continue to rise to the challenge and focus on refining the micro micro injection moulding (μ-MIM®) method in particular.

Joined TAISEI KOGYO Co., Ltd. in 1982. After becoming a Director in 1984, he rose to become President and Representative Director in 1992. Earned a doctorate from the Kyoto Institute of Technology Graduate School. Inaugurated as Representative Director and President of Japan Micro MIM Holdings, Inc. in December 2017 . Hobbies include skiing and off-season training.

Embrace change and make that “something” happen in future

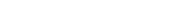

Above all, adamant that is the MIM pursuit of high quality is what underpins its prowess in micronisation, we have individually addressed issues affecting each part of the manufacturing process. These include, for example, selecting the raw materials and binders specialised for μ-MIM use, evaluating the homogeneity of mixing and reviewing the improvement method, introducing the micro-injection moulding machine and optimising the moulding conditions , stabilising degreasing / sintering processes as well as devising means of evaluation on a microscopic scale to date. To maximise quality, we have focused on the following areas above all:

Among these approaches, μ-MIM® is a form of manufacturing technology based on general-purpose MIM technology, but boosting quality and functionality . From this perspective, while promoting “MIM with Engineering”, we have also been striving to establish μ-MIM system technology as a new approach to manufacturing that goes beyond the scope of downsizing products along. We see our key mission as meeting the demands of many customers and mass-producing goods by leveraging advanced technology.

*Remark : This newsletter was originally published on March 27, 2018