Micro-MIM Newsletter Vol.44: Diameter less than 1 mm, module of < 0.3 mm!

Diameter less than 1 mm, module of < 0.3 mm!

As many kinds of precision devices are getting smaller and lighter, gears in the devices are also required to become smaller and lighter. It is difficult to machine small special-shaped gears, such as bevel and helical gears, less than a few millimeters in diameters. However, Taisei Kogyo Co., Ltd., our group company, has challengingly continued to research and develop special-shaped micro gears manufacturing by μ-MIM® technology. MIM (metal powder injection moulding) is commonly deployed for serial production of gears but our μ-MIM® technology manufactures special small gears with stable quality.

High precision processing by μ-MIM®

– Dimensional accuracy ±0.1% is achieved

The MIM process begins with mixing metal powder and binder resins to compose feedstock. The feedstock is injected into the mould to form the component, and followed by debinding and sintering to gain the metal component. Unlike the plastic injection moulding, the MIM process does involve a debinding and sintering step, where the components shrink more than 10%. Therefore, most of the MIM manufacturers do secondary processing such as machining for achieving net shape. However, our μ-MIM® technology, goes beyond conventional MIM, is able to manufacture net-shaped components at as sintered.

Here are some examples of gears that we manufactured below. If you’re interested, please check out the difference between conventional MIM and μ-MIM® here.

Planet gears: φ 2.0 mm

Integrated gear: φ 0.6 mm

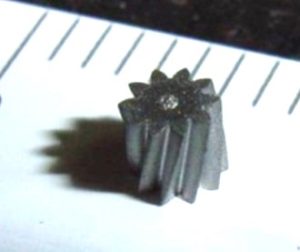

Helical gear: φ 2.0 mm

Sun gear: φ 0.85 mm

Machining vs μ-MIM®

Almost all kinds of shapes are realisable by making full use of 5-axis machine tools and computer-aided manufacturing softwares, however, more and more complex the shape is, harder and harder it gets to realise high precision, which increases the processing time and costs. For example, spiral bevel gears, helical gears and internal helical gears are typical gears whose difficulty and costs are high when they are manufactured by cutting.

These above parts require a long processing time when they are manufactured by cutting or machining, thus, high volume serial production is limited. In some case, to keep the manufacturing costs low, they modify the design components to be processed by a lathe, milling machine, or NC (general 3-axis machining center).

However, our μ-MIM® realises stable mass production of those components, even this helical gear, which is impossible to be demould from a standard mould structure. Additionally, unlike the machining we do not need to re-setting the chucking, the locational tolerance requirement is also highly achieved. Plus, our 3D-μMIM, a part of our μ-MIM® technology, unlimit the design freedom, thus any ideal gear will be stable mass produced by μ-MIM®.

In the next issue of our newsletter, we will explain how to solve this problem and advantages of manufacturing gears by μ-MIM®.

Machining vs μ-MIM®

In Japan, many people are obsessed with a particular kind of flower – Sakura (cherry blossom)! You probably have seen in the media that many Japanese people have a picnic under the cherry blossom trees. Cherry blossoms bloom between the end of March and the end of April depending on where in Japan you are located. As some workers move departments or freshmen start to work in this season because the Japanese school and business year starts in April and ends in March, thus, welcome or farewell parties of companies are often hold under the cherry blossom trees. If you are willing to travel to Japan, we highly recommend this beautiful season to visit Japan!