Technical Newsletter vol.7 : Expanding demand of stainless steel in many industries

Expanding demand of stainless steel in many industries

It is continuously expanding the demand for stainless steel due to its excellent corrosion resistance and functionality in many industries. Stainless steel is roughly divided into 4 groups, which are austenitic type, ferritic type, martensitic type and precipitation hardening type. It is said that there are more than 100 of stainless steel varieties. It is important to select the appropriate stainless steel material for each product. In this newsletter we will introduce representative stainless steel types that we have applied to our mass production.

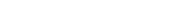

SS316L : Austenitic stainless steel

– High corrosion resistance and widest application –

SS316L is Mo added to 304 and lower carbon contents. While, the surface hardness, tensile strength is inferior to other steel types, however it has the best corrosion resistance and high temperature strength among stainless steels. Machining is difficult due to its remarkable work hardening property. It is one of the best materials to demonstrate beneficial effects of MIM.

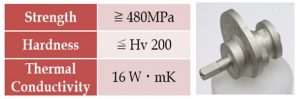

SS630 : Precipitation hardening type stainless steel

– Good corrosion resistance with high strength –

SS630 is copper added to increase the hardness by heat treatment (H900). It is austenitic stainless steel thus also good in corrosion resistance. In recent years, medical industry application is increasing.

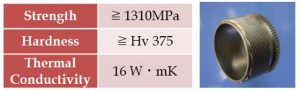

SS410L : Ferritic stainless steel

– Gaining attention as a soft magnetic material –

Since SS410L is moderately adjusted the additives, thus it remains ferrite even at high temperature, and the coefficient of thermal expansion is lower than other stainless steel. Even its lower strength and corrosion resistance, the demand is increasing due to the magnetic properties in downsizing sensors and motors applications.

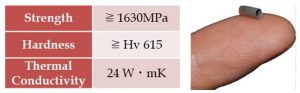

SS440C : Martensitic stainless steel

– High hardness by heat treatment –

SS440C contains relatively high amount of carbon. The mechanical properties will change depending on tempering conditions, though it is applied for components which required high strength and hardness. Due to its low processability, MIM can maximise the benefit of this material in mass production of small complicated design components.

COLUMN

I am Kenji Okubo in charge of technology development. For 15 years, I have experienced from design or research and development, to mass production. Nowadays I am trying hard to realise mass production of difficult designs. My motto in work is “Do not rush” As workload increases, I will be impatient and I may not be aware of the original “awareness” and take a detour.

My hobby is drum performance. Recently, I have organised a big band and have appeared in jazz festival a few times a year. I have an 1 year old girl and she has very strong power to make me rush to home every day.

*Remark : This newsletter was originally published on January 15, 2019