Technical Newsletter vol.12 : Binders for Micro MIM

Binders

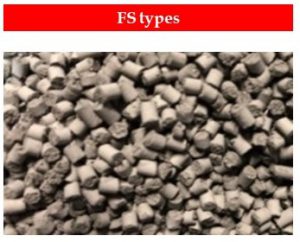

Metal injection moulding or MIM is a method of manufacturing metal parts by injecting feedstock (FS), made by kneading metal powder with a thermoplastic resin called binder, into a mould. This binder does not remain in the final product, but it plays an important role in determining the quality of the final product. This is an introduction to the impact of binders in metal injection molding or MIM, which can obtain the final shape without post-processing and the subsequent sintering process.

Mass producing small complex shapes is the greatest feature of MIM. A binder is indispensable for moulding, which is the only process of forming. Appropriate FS maintains high fluidity, filling, good releasability to mould, and increases mass productivity. However, since the binder is organic, if it remains in the final product, it degrades the mechanical properties. For this reason, most of the binder is decomposed after molding in a process called degreasing. The small amount of binder that remains after this degreasing process remains in the final shape until the metal powders are bonded together in the sintering process. Any binder remaining after the degreasing process is then completely decomposed in the sintering process.

It is possible to categorise binders for metal injection molding or MIM feedstock in 3 types : 1) water-soluble, 2) solvent-thermal decompose and 3) catalytic decompose. Water-soluble binder is decomposed with water, and solvent-thermal binder is decomposed with organic solvent or heat. Catalytic decompose binder is also decomposed by heat, but the binder is decomposed in an acid atmosphere at lower temperature than the thermal decompose type. Since it is treated in an acid atmosphere, the applicable metals are limited. Any feedstock can be purchased, but it often takes time until new metal powders, such as smaller particle size and new alloy-based powders, are employed.

Our company produces in-house feedstock. Appropriate binders are selected for the metal, and even when the same type of metal is used in mass production, depending on the product shape the feedstock is optimised. Due to the compatibility with the latest metal powder, production with new materials can be proposed upon request. The plastic injection moulding technology we have cultivated since our founding supports the binder, feedstock development and moulding technology. Therefore we are able to provide state-of-the-art products to our clients.

We are ISO13485 certified

For more information : ISO Certificate

Taisei Kogyo Co., Ltd., the manufacturing department of Micro MIM Japan, acquired ISO13485 certification in May 2019. For customers who are in medical industries, the reliability of our quality assurance can be further enhanced. Micro MIM Japan will continue to actively contribute to the medical field through µ-MIM technology.

COLUMN

Japanese national summer holiday Obon

In August we have a period of 4 days holidays called Obon. During this period, many people go back to their hometown to visit their ancestors graveyard. On 13th, we invite the ancestors‘ souls to our home, then on 16th, we go to the graveyard again to let the ancestors‘ souls return. People pray to their ancestors at the Butsudan, a small wooden house shrine, on daily basis. During Obon, there are special lanterns placed next to this Butsudan. Many summer festivals are held during Obon, e.g. the famous Bon-odori dance. Many people wear Yukata, traditional summer clothes. At these festival you can enjoy stands selling street food, sweets, small toys and more.

*Remark : This newsletter was originally published on September 5, 2019