Production Technology

Micro Metal Injection Moulding (μ-MIM®) Technology Development

Our micro metal injection moulding (micro MIM or μ‐MIM®) technology is developed to manufacture extremely small and complex metal parts with high dimensional accuracy.

Metal injection moulding enables the mass production of precision micro components that are difficult to achieve through conventional machining or casting methods.

Our μ‐MIM® process extends the potential of traditional metal injection moulding to a micro level, achieving both miniaturisation and exceptional quality.

What Is Micro Metal Injection Moulding (μ-MIM®)?

Micro MIM (μ‐MIM®) is an advanced processing technology derived from metal injection moulding (MIM). It allows the creation of micro-sized, high-precision metal components with micron-level control.

This innovative metal injection moulding technology is increasingly in demand due to the growing trend of miniaturisation across industries such as medical devices, electronics, and precision instruments.

By applying metal injection moulding principles at a microscopic scale, μ‐MIM® offers high accuracy, material density, and design flexibility.

Advantages of Micro Metal Injection Moulding (μ-MIM®)

Our micro metal injection moulding (μ‐MIM®) process provides significant advantages compared with other metal manufacturing technologies:

- 1. Machining: Reduced processing cost for complex designs, improved productivity, and shorter delivery times

- 2. Stamping: Enables more complicated designs with higher dimensional accuracy

- 3. Pressure die casting: Offers wider material options and higher mechanical properties

- 4. Lost-wax process: Supports larger manufacturing lot sizes with higher accuracy

- 5. Powder metallurgy compaction: Delivers better mechanical strength and design freedom

- 6. Additive manufacturing: Allows higher productivity and more material flexibility

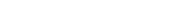

The main difference between conventional metal injection moulding (MIM) and our micro MIM (μ‐MIM®) is the precision and miniaturisation capability.

Our technology pushes beyond the limitations of standard metal injection moulding.

Feedstock and Binder System for Metal Injection Moulding

To achieve the highest quality in metal injection moulding, we have developed our own feedstock system. The binder composition is a critical factor in ensuring dimensional accuracy and material integrity.

Our in-house formulation process optimises the ratio of metal powder to binder, allowing us to control shrinkage, density, and mechanical properties across each metal injection moulding project.

This proprietary approach ensures that every μ‐MIM® component meets the strictest quality requirements.

Micro Powder in Metal Injection Moulding Process

The metal injection moulding process is one of the most advanced powder metallurgy (PM) techniques, achieving the highest sintered density among PM processes.

Conventional PM parts typically have rough surfaces, requiring additional polishing. In contrast, our micro metal injection moulding technology utilises ultra-fine metal powder to achieve a smooth surface finish and sophisticated exterior.

This makes metal injection moulding ideal for applications demanding both precision and aesthetics.

Advanced Mould Design for Stable Metal Injection Moulding Quality

With decades of experience in mould design, combined with modern flow analysis and evaluation systems, we have achieved outstanding precision in our moulding processes.

In metal injection moulding, the positioning and design of the gate are far more delicate than in plastic injection moulding.

Because the density difference between metal powder and polymer is significant, improper gate design may cause uneven powder distribution, leading to cracks or defects during sintering.

Our accumulated know-how in metal injection moulding design, simulation, and evaluation ensures stable quality and reproducible results for our products.