Business outline

Business outline

To realize products impossible by existing manufacturing technology

Technical collaboration/ Innovation to customers with our R & D capabilities

Provide cutting-edge processing technology worldwide, centring on self-developed micro MIM (μ-MIM®) technology

Micro MIM Japan Holdings Inc. offers technology cooperation with various technologies that we have cultivated by providing technology transfer. We will support our customer’s open innovation with multifaceted proposals from many new technologies that we have nurtured, including our micro MIM (μ-MIM®) technology that we are proud of. Please make us an inquiry with your ideas.

Contracted analysis & measurement/ Quality assurance with the world’s most advanced measurement and analysis

With innovative evaluation technology, we will respond to your needs quickly and certainly. Micro MIM Japan Holding Inc. solves customer’s problems through analytical evaluation technology with numerous evaluation techniques that we have cultivated up to now.

Many of the products realised with micro MIM (μ-MIM) technology are difficult to position, not able to chuck in the first place and can not include probes of contact type three-dimensional measuring instruments. Also, we have experienced a number of new alloy systems and products with trace amounts of contaminants that affect functionality. Therefore, Micro MIM Japan Holdings Inc. has established a quick and reliable evaluation system directly linked to development speed.

3D morphology measurement technology

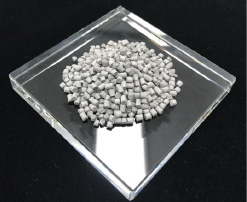

Material sales business/ In-house developed feedstock (MIM raw material pellets)

Innovative metal injection moulding(MIM) raw material pellets designed for high-precision MIM, enabling complex-shaped parts with outstanding dimensional accuracy.

Micro MIM Japan Holdings Inc. offers original-recipe feed stock (MIM raw material pellets).

Regardless of metal type or alloy type, it exerts its power in areas that were difficult in the past. They are suitable for serial production components with very thin wall thickness, high dimensional accuracy and high process capability index. It is innovative MIM feedstock which expands its usage to high precision and high quality as well as miniaturization of the parts. Please feel free to inquire us about the feedstock not only for MIM usage.